INKWELL DESIGN SOLUTION

Established in 2018 & registered in 2024 by Atiq ur Rehman & Azed Riyan, Inkwell design solutions has been built on the principles of providing our customers with a professional service for all their design requirements. Serving a variety of industries, we provide both detailed 2d and 3d designs using industry leading software. Due to continual investment, we have grown to become one of the Maharashtra’s largest independent design houses. Also, we provide the manufacturing services to required customers.

Crafting groundbreaking designs with passion and precision, pushing boundaries to redefine industry standards and inspire innovation globally.

ABOUT OUR TEAM

Our team is made up of six design engineers who all bring years of experience on board in varying sectors, including automotive press tool design and general engineering. Unlike other firms our expertise and involvement doesn’t end once the designs have been created – here at Inkwell Design Solutions we pride ourselves on our extended manufacturing assistance and customer support throughout the entire manufacturing process.

01.

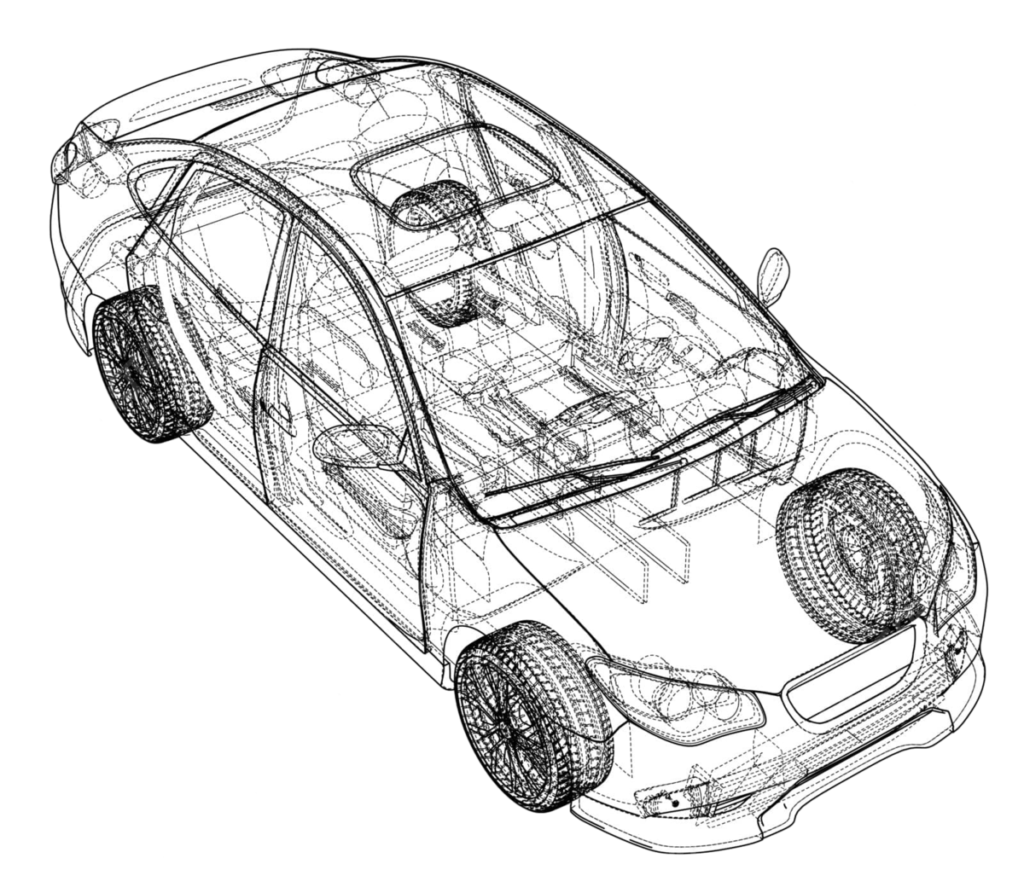

Aesthetical and Precise Autoparts & Design

02.

03.

What Can We Offer

PROGRESSION

We are specialists in designing progression tooling primarily for the automotive and house building sectors.

TRANSFER

We design a range of transfer tooling, from deep draws for the canning industry to structural body parts for the automotive industry.

SINGLE OP

We design single op tooling to suit our customers requirements. Either for low volume production or to suit a customers press set up..

JIGS/ FIXTURES

We design jigs and fixtures for a variety of uses, from final checking fixtures to assembly, weld and laser fixtures.

Deep draw

Deep draw tooling requires significant feasibility analysis before design comences, us ing Autoform we give our customers confidence of a process before manufacture starts. .

Hot form

We design hot form and die quench tooling primarily for automotive and aerospace industries, whether it is the material, dies or both that require heating we have the experience..

Tooling Products

Completed Projects

Years of Team Experience

Teams

Our Softwares Partners

The primary design software we use are CATIA, FORMING SUITE and AUTOFORM. This choice of software provides our clients with a more productive and efficient design service by reducing the risk of error and increasing manufacturing productivity.

- Semi-automatic results evaluation

- Fully and authentically mapped engineering workflow into the simulation data

- Easy and fast issue identification and interpretation

- Rapid assessment of process feasibility.

- A dedicated software for the design of progressing dies and press tools.

- Gives full 3D modelling and surfacing design capabilities.